|

| |

nextnano3 - Tutorial

next generation 3D nano device simulator

1D Tutorial - Part 6

Piezoelectric fields due to strain (Quantum well)

Information on strain can also be found in the

FAQ

section and in the strain tutorial.

Author: Stefan Birner

If you want to obtain the input files that are used within this tutorial, please

check if you can find them in the installation directory.

If you cannot find them, please submit a

Support Ticket.

->

1Dpiezo_Al0.70In0.30As_In0.53Ga0.47As_100_nn3_growth_along_z_direction.in - input file for the nextnano3 software

1Dpiezo_Al0.70In0.30As_In0.53Ga0.47As_311_nn3_growth_along_z_direction.in - input file for the nextnano3 software

1Dpiezo_Al0.70In0.30As_In0.53Ga0.47As_100_nn3.in / *_nnp.in - input file for the nextnano3 and nextnano++ software

1Dpiezo_Al0.70In0.30As_In0.53Ga0.47As_311_nn3.in / *_nnp.in -

1Dpiezo_Al0.33In0.67As_In0.32Ga0.68As_111_nn3.in / *_nnp.in -

Input files for nextnano.MSB and nextnano.NEGF software for this

tutorial are also available.

Piezoelectric fields

Piezoelectricity is due to the ionicity of III-V semiconductor compounds.

Si

and Ge have purely covalent bonds whereas the bonds of III-V compounds are

partially ionic (heteropolar) because the electrons spend on average more time

next to the (negatively charged) anions.

Zinc-blende structures are piezoelectric materials. Off-diagonal strain

tensor components (j≠k)

induce a polarization given by

Pis = 2 e14 epsilonjk

(epsilon = strain tensor)

where Ps is the induced polarization, e14 is

the piezoelectric constant and epsilonjk is a symmetrized

strain component.

However, diagonal strains (epsilonxx, epsilonyy, epsilonzz) do not

induce a polarization (i.e. e11=0).

A strained layer superlattice with a [001] growth direction will induce only

diagonal strains; but with any other growth direction, off-diagonal strains also

occur.

Thus [001]-growth axis strained-layer heterostructures will not have

strain-induced polarization fields, but strained-layer heterostructures with any

other growth direction will have these polarization fields.

Because one of the constituent materials is in biaxial tension and the other is

in biaxial compression, the polarization vector changes sign at the interface.

For a [111] growth axis, Ps is parallel to the growth axis,

for a [110] growth axis, Ps is in the interface plane; for

a [001] growth axis, Ps vanishes.

For a general growth axis,

Ps has components both parallel and perpendicular to the

growth axis.

The resulting interface charge density is given by

rho = - div Ps.

==> Text taken from D.L. Smith, C. Mailhiot, Rev.

Mod. Phys. 62 (1), 173 (1990)

Thus we want to test this on a quantum well structure consisting of Ga0.47In0.53As

(quantum well) and AlxIn1-xAs (barrier).

We will try 3 growth directions for Al0.70In0.30As.

- [001] - no strain-induced polarization fields (E=0)

- [011] - polarization vector Ps lies

in the interface plane

- [111] - polarization vector Ps is perpendicular to

interface and parallel to growth direction

(A superlattice grown in [111] direction has a different point group symmetry,

namely C3v, than [001] growth which is D2d.)

We will also try growth direction [111] with different alloy compositions

for the barrier resulting in different piezoelectric constants for each barrier

material.

- Al0.63In0.37As

- Al0.33In0.67As

Ga0.47In0.53As/Al0.48In0.52As is

lattice matched to InP.

By proper

choice of alloy composition of AlxIn1-xAs, one can subject

this layer to either tensile or compressive strain when grown

pseudomorphic on InP leading to a splitting in light hole (lh) and heavy hole (hh)

bands and also changing their order.

Okay, let's compare the growth directions for a Ga0.47In0.53As

- Al0.70In0.30As quantum well.

|

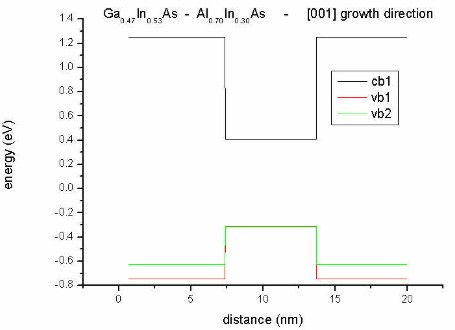

- along [001] direction

==>

1Dpiezo_Al0.70In0.30As_In0.53Ga0.47As_100_nn3_growth_along_z_direction.in

Splitting due to strain: The heavy hole band (vb1)

is lower than the light hole band (vb2) of Al0.70In0.30As

(barrier) due to tensile strain.

Due to the [001] growth direction, no piezoelectric charges are present.

|

|

|

Conduction

and

valence bands

along [001] |

|

|

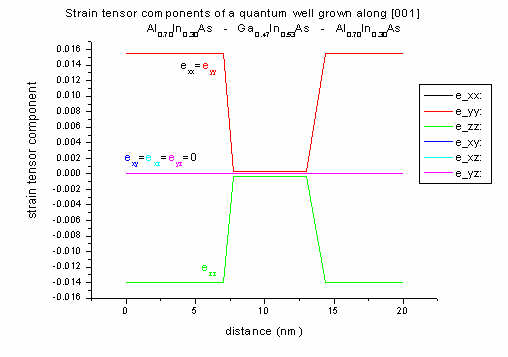

Strain

along [001] |

|

[001] growth direction: The well region is lattice matched to

InP, therefore strain is zero. Only the barrier region is subject to

strain. The off-diagonal strain tensor components are all zero (exy=exz=eyz=0)

as we have [001] growth direction. Al0.70In0.30As has

a smaller lattice constant than the substrate material InP (lattice mismatch

1.55 %) leading to tensile strain.

In 1D strain can be calculated analytically along [001] growth direction:

(a = lattice constant, c11, c12 = elastic constants):

Biaxial strain (in plane of interface):

exx = eyy

= ( asubstrate - alayer ) / alayer = 0.0155 (1.55 % lattice mismatch)

Uniaxial strain (perpendicular to interface):

ezz = - 2 (c12/c11) exx

= - 0.014

For [001] growth direction, crystal and simulation system coincide. Thus the

strain given in the crystal coordinate system is equal to the strain given

in the simulation system.

|

|

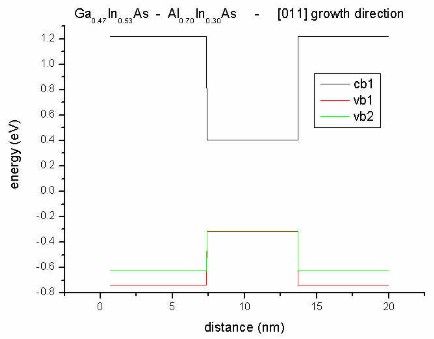

- along [011] direction

changes in input file:

hkl-z-direction-zb = 0 1 1 ! Miller indices of

z

coordinate axis [0 0 1]

hkl-y-direction-zb = 0 1 -1 !

There's no effect due to piezoelectric charges as the polarization vector

is directed along the interface (perpendicular to growth direction).

|

|

|

Conduction

and

valence bands

along [011] |

|

|

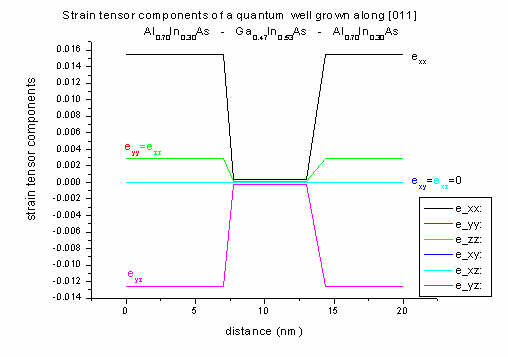

Strain

along [011] |

|

[011] growth direction: The well region is lattice matched to InP,

therefore strain is zero. Only the barrier region is subject to strain.

exx again can be calculated analytically as above with the same

result. The off-diagonal strain components that include x are zero (exy=exz=0).

Due to shear strain in the (y,z) plane, eyz is not zero.

Al0.70In0.30As has a smaller lattice constant than the

substrate material InP (lattice mismatch 1.55 %) leading to tensile strain.

In 1D layered heterostructures, strain can be calculated analytically along [011] growth direction (see

FAQ section). The strain tensor components can

be printed out with respect to the crystal

coordinate system and simulation coordinate

system (see keyword

$output-strain).

For [011] growth direction, crystal and simulation system do not

coincide anymore. Thus the strain given in the crystal coordinate system is

not equal to the strain given in the simulation system anymore.

In the simulation system all off-diagonal components of the strain tensor

are zero (exy,sim=exz,sim=eyz,sim=0) and eyy,sim=ezz,sim.

|

|

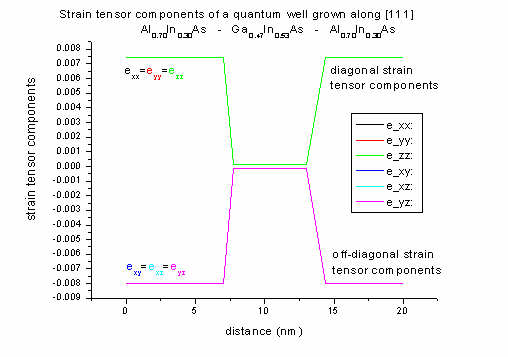

- along [111] direction

changes in input file:

hkl-z-direction-zb = 1 1 1 ! Miller indices of z

coordinate axis [1 1 1]

hkl-y-direction-zb = 0 1 -1 !

The polarization vector due to piezoelectric charges is directed along the

[111] growth direction leading to a slope in the conduction and valence

bands.

|

|

|

Conduction

and

valence bands

along [111] |

|

Strain

along [111] |

[111] growth direction: The well region is lattice

matched to InP, therefore strain is zero. Only the barrier region is subject

to strain.

In 1D strain can be calculated analytically along [111] growth direction (see

FAQ section).

The off-diagonal strain components (shear strain) are all equal (exy=exz=eyz).

Al0.70In0.30As has a smaller lattice constant than the

substrate material InP (lattice mismatch 1.55 %) leading to tensile strain.

For [111] growth direction, crystal and simulation system do not coincide

either. Again, the strain given in the crystal coordinate system is not

equal to the strain given in the simulation system.

In the simulation system all off-diagonal components of the strain tensor

are again zero (exy,sim=exz,sim=eyz,sim=0)

and eyy,sim=ezz,sim.

Note: For [321] growth direction eyz,sim=0 but all other

off-diagonal compontents are not zero anymore. In the simulation system, for

any growth direction, eyy,sim=ezz,sim=exx,sim[111]=exx,sim[hkl].

For the pictures above, the strain tensor components are plotted with

respect to the

crystal coordinate system, not simulation coordinate system.

|

|

| |

|

| Discussion of piezoelectric field |

|

| For the [111] case the polarization vector is along [111].

As expected we get an electric field. For [011] the polarization vector

lies in the interface (no resulting E field) and for [001] there isn't any

polarization verctor. |

| |

|

([111] growth: If you change the piezoelectric constant e14

in the database_nn3.in file

to zero, you won't get a slope and the picture looks as for the [001] case.

If you change the signs of these constants from negative to positive, the

slope would be reversed. The direction depends on the sign, e.g.

positive from In (cation) to As (anion) along [111].)

You can also switch of piezoelectricity using the flag piezo-constants-zero =

yes in

$numeric-control.

|

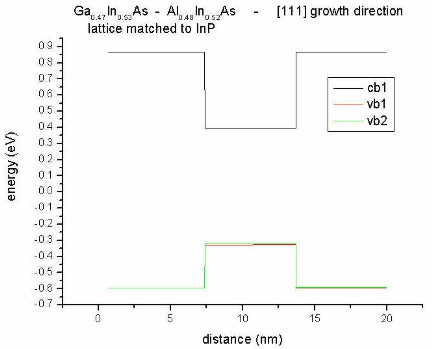

- along [111] direction

Again we take the [111] direction but this time we take lattice matched Ga0.47In0.53As

and Al0.48In0.52As (lattice matched to InP) herby

avoiding any strain. Thus we do not get any heavy hole/light hole

splitting. Without strain we even don't get piezoelectric charges and thus

no slope.

|

|

|

|

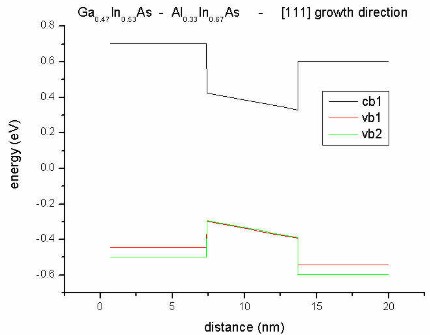

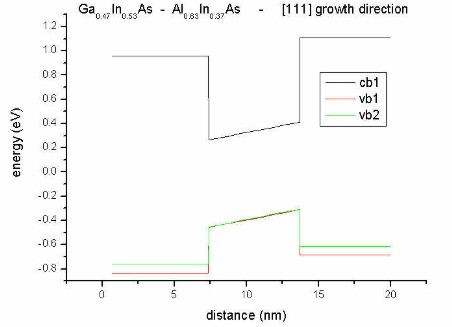

- along [111] direction

Here, we change the alloy composition of the barrier.

(strain calculation: pseudomorphic on InP substrate:

homogeneous-strain)

- biaxial compression for Al0.33In0.67As

- biaxial tension for Al0.63In0.37As

- still no strain for the well

Now the electric field resulting from piezoelectric charges changes its direction

in the two cases.

The heavy hole (vb1) / light hole (vb2)

splitting is also different in these two cases!

|

|

|

biaxial compression

for

Al0.33In0.67As |

|

|

biaxial tension for:

Al0.63In0.37As |

|

|

|

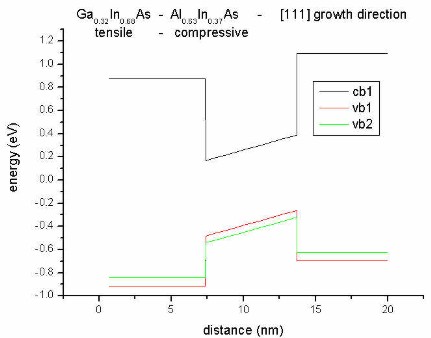

- along [111] direction

Our substrate is InP.

We now combine compressive (Ga0.32In0.68As) and

tensile (Al0.63In0.37As) strain. Now for

both materials, heavy hole (vb1) and light

hole (vb2) bands split but into opposite

directions.

|

|

|

biaxial tension for:

Al0.63In0.37As

(barrier)

biaxial compression

for:

Ga0.32In0.68As

(well) |

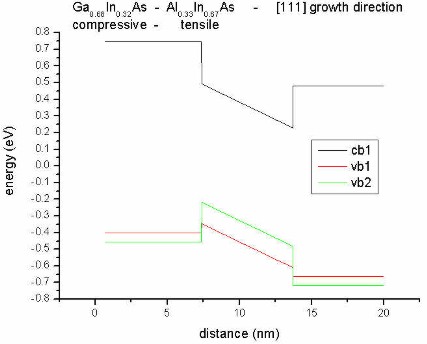

- along [111] direction

==> 1Dpiezo_Al0.33In0.67As_In0.32Ga0.68As_111_nn3.in

Our substrate is InP.

We now combine tensile (Ga0.68In0.32As)

and compressive (Al0.33In0.67As) strain. Now for

both materials, heavy hole (vb1) and light

hole (vb2) bands split again but into

opposite directions and into opposite directions compared to the previous

pictures.

|

|

|

biaxial compression for:

Al0.33In0.67As

(barrier)

biaxial tension

for:

Ga0.68In0.32As

(well)

|

|

|

|

Step 1: Quantum well structure - Piezoelectric fields

- The structure is grown pseudomorphic on an InP substrate.

- We perform a one-dimensional simulation.

- Just a reminder: If you need additional information about the keywords and

their specifiers, you can look it up

here.

- The heterostructure looks like this:

! barrier

well

barrier

! 1

2

3

!

! Al(x)In(1-x)As In(x)Ga(1-x)As

Al(x)In(1-x)As

! 7

6

7 nm

!___________________________________________________

- The structure has no doping.

- Output

- The band structure will be saved into the directory band_profile/

- The densities will be saved into densities/

- The strain will be saved into strain/

- The material parameters will be saved into material_parameters/

- You should be able to modify the appropriate lines in the input file

1Dpiezo.in

in order to reproduce the results shown above.

$domain-coordinates

...

$end_domain-coordinates

$alloy-function

...

$end_alloy-function

|